Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. This process is widely utilized in the production of plastic parts, which are essential components in various industries such as automotive, electronics, and consumer goods. Among the different types of injection molding machines, large horizontal injection molding machines stand out due to their unique capabilities and applications.

What is a Large Horizontal Injection Molding Machine?

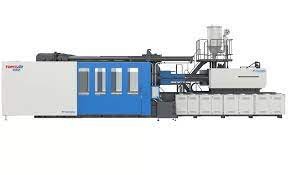

A large horizontal injection molding machine is a type of machinery used to manufacture substantial plastic parts. These machines are characterized by their horizontal orientation, where the mold clamping unit and the injection unit are aligned horizontally. This orientation allows for easier handling of large molds and facilitates the production of large, complex parts.

Components of a Large Horizontal Injection Molding Machine

- Clamping UnitThe clamping unit is responsible for holding the mold in place during the injection process. It applies the necessary force to keep the mold closed while the molten plastic is injected and solidified. In large horizontal machines, the clamping force can range from 1,000 to over 8,000 tons, depending on the size and complexity of the part being produced.

- Injection UnitThe injection unit is where the plastic material is melted and injected into the mold. It consists of a hopper, screw, barrel, and nozzle. The plastic granules are fed into the hopper, melted in the barrel, and then injected into the mold cavity through the nozzle. The screw’s movement and rotation ensure the consistent melting and mixing of the plastic material.

- MoldThe mold is a critical component that defines the shape and features of the final product. It consists of two halves: the cavity and the core. When the mold is closed, these halves form the mold cavity where the molten plastic is injected. Molds can be highly intricate, with multiple cavities to produce several parts simultaneously.

- Hydraulic SystemLarge horizontal injection molding machines typically use a hydraulic system to control the clamping and injection processes. The hydraulic system provides the necessary force and precision to operate the machine efficiently. Some modern machines also incorporate electric or hybrid systems for improved energy efficiency and control.

- Control SystemThe control system is the brain of the injection molding machine. It monitors and regulates the various parameters of the injection process, such as temperature, pressure, injection speed, and cooling time. Advanced control systems offer high precision and automation, allowing for consistent and repeatable production cycles.

Advantages of Large Horizontal Injection Molding Machines

- Production of Large PartsOne of the primary advantages of large horizontal injection molding machines is their ability to produce large parts. This capability is essential in industries such as automotive, where components like bumpers, dashboards, and panels are manufactured. The horizontal orientation makes it easier to handle large molds and ensures uniform filling of the mold cavity.

- High Efficiency and ProductivityLarge horizontal machines are designed for high-volume production. They can operate continuously with minimal downtime, ensuring high efficiency and productivity. The ability to produce multiple parts in a single cycle, using multi-cavity molds, further enhances their production capacity.

- Precision and ConsistencyModern large horizontal injection molding machines are equipped with advanced control systems that ensure precise control over the injection process. This precision results in consistent part quality, reducing the need for post-processing and minimizing material waste.

- VersatilityThese machines are highly versatile and can process a wide range of plastic materials, including thermoplastics, thermosets, and elastomers. This versatility allows manufacturers to produce parts with varying properties, from rigid and durable to flexible and elastic.

Applications of Large Horizontal Injection Molding Machines

- Automotive IndustryThe automotive industry is one of the largest consumers of injection molded parts. Large horizontal injection molding machines are used to produce components such as bumpers, dashboards, door panels, and interior trims. The ability to manufacture large, complex parts with tight tolerances is crucial for the automotive sector.

- Consumer GoodsMany everyday items, from large storage containers to furniture components, are produced using large horizontal injection molding machines. The efficiency and precision of these machines make them ideal for high-volume production of consumer goods.

- ElectronicsIn the electronics industry, large injection molded parts are used in products like television housings, computer monitors, and large appliance casings. The high precision of these machines ensures that the components fit perfectly and meet the required specifications.

- Industrial ApplicationsIndustrial applications often require robust and durable plastic parts. Large horizontal injection molding machines are used to produce components for machinery, equipment, and industrial containers. Their ability to handle large molds and produce parts with high structural integrity is essential for these applications.

Challenges and Considerations

- High Initial InvestmentLarge horizontal injection molding machines represent a significant investment. The cost of the machine itself, along with the necessary molds and auxiliary equipment, can be substantial. However, the high production efficiency and quality can justify the initial expenditure over time.

- Space RequirementsThese machines require considerable floor space due to their size and horizontal orientation. Manufacturers need to ensure that they have adequate space for installation and operation, as well as for mold storage and material handling.

- Maintenance and OperationProper maintenance is crucial to ensure the longevity and optimal performance of large horizontal injection molding machines. Regular inspections, cleaning, and servicing of the hydraulic system, molds, and other components are necessary. Additionally, operators need to be trained to handle the machine’s complexities and troubleshoot any issues that arise.

Future Trends in Large Horizontal Injection Molding Machines

- Automation and Industry 4.0The integration of automation and Industry 4.0 technologies is transforming the injection molding industry. Large horizontal machines are increasingly being equipped with sensors, robotic arms, and advanced control systems that enable real-time monitoring, predictive maintenance, and process optimization. This shift towards smart manufacturing enhances efficiency, reduces downtime, and improves overall product quality.

- Sustainability and Energy EfficiencyWith growing environmental concerns, manufacturers are focusing on making injection molding processes more sustainable. Innovations such as energy-efficient hydraulic systems, hybrid machines, and the use of recycled materials are gaining traction. These advancements help reduce energy consumption, lower carbon footprints, and promote eco-friendly manufacturing practices.

- Material InnovationsThe development of new plastic materials with enhanced properties is expanding the capabilities of large horizontal injection molding machines. High-performance polymers, bio-based plastics, and composites are being used to create parts with improved strength, durability, and environmental sustainability.

Conclusion

Large horizontal injection molding machines play a vital role in modern manufacturing, enabling the production of large, complex plastic parts with high precision and efficiency. Their applications span various industries, from automotive to consumer goods, electronics, and industrial sectors. Despite the challenges of high initial investment and maintenance, the benefits of high production capacity, versatility, and consistent quality make these machines indispensable in the injection molding industry. As technology advances, the future of large horizontal injection molding machines looks promising, with trends towards automation, sustainability, and material innovation driving further improvements in their capabilities and performance.

4o