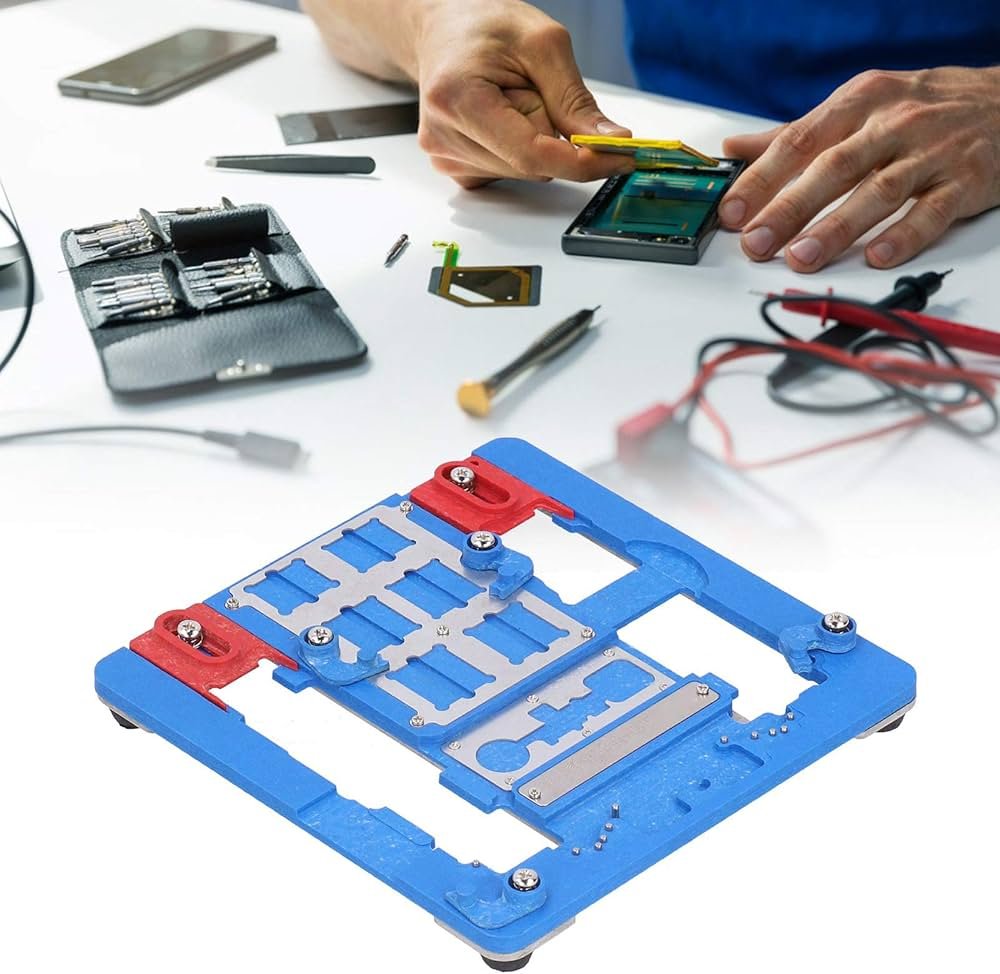

Smartphone motherboards, also known as PCBs, are the most complex and delicate components inside modern mobile devices. They contain densely packed chips, connectors, and micro-circuits that require extreme precision during repair. To work safely and accurately on these components, technicians rely on specialized equipment such as the phone motherboard repair fixture and phone PCB repair fixture. These tools are essential for stabilizing circuit boards and ensuring consistent, high-quality repair results.

A phone motherboard repair fixture is designed to securely hold a smartphone PCB in place during repair procedures. Whether performing micro-soldering, chip replacement, jumper wire installation, or fault diagnosis, stability is critical. Even slight movement can lead to misalignment, poor solder joints, or damage to sensitive components. Repair fixtures provide a firm, adjustable platform that keeps the motherboard steady throughout the repair process.

Similarly, a phone PCB repair fixture supports various phone motherboard shapes and sizes. Many fixtures feature adjustable clamps or modular holders that accommodate different phone models, including both iPhone and Android devices. This versatility makes them a valuable tool for professional repair shops that service a wide range of smartphones.

One of the primary advantages of using a PCB repair fixture is improved precision. By holding the motherboard at a fixed angle and position, technicians can work under microscopes with greater accuracy. This is especially important for tasks such as BGA reballing, CPU rework, and connector repairs, where even microscopic errors can cause device failure. A stable fixture allows for better hand control and more consistent soldering results.

Heat management is another important benefit. During hot air rework or soldering, uncontrolled movement can lead to uneven heat distribution and component damage. Phone motherboard repair fixtures help maintain proper board alignment, ensuring that heat is applied evenly and safely. Some advanced fixtures are made from heat-resistant materials that can withstand high temperatures without warping or deforming.

Efficiency and workflow optimization are also key advantages. With a reliable PCB repair fixture, technicians can complete repairs faster and with fewer mistakes. The ability to quickly mount and remove motherboards reduces downtime and improves productivity, particularly in busy repair environments. This efficiency translates into faster turnaround times and higher customer satisfaction.

Durability and build quality play a major role in professional fixtures. High-quality phone PCB repair fixtures are typically constructed from aluminum alloy or stainless steel, offering excellent strength and long-term reliability. Precision-machined components ensure consistent clamping pressure without damaging the motherboard.

In conclusion, the phone motherboard repair fixture and phone PCB repair fixture are indispensable tools for modern smartphone repair. They provide stability, precision, and efficiency for complex motherboard-level repairs. Whether used in a professional repair shop or by an experienced technician, these fixtures help ensure accurate workmanship, reduce repair risks, and deliver dependable, professional-grade results.